Daftar isi :

PELATIHAN PIPING AND PIPELINE: DESIGN, INSTALLATION, OPERATION

TRAINING DESIGN OF PIPING AND PIPELINE

TRAINING PIPING AND PIPELINE: DESIGN, INSTALLATION, OPERATION

DESKRIPSI PELATIHAN INSTALLATION OF PIPING AND PIPELINE

This special practical approach course is designed to provide a comprehensive understanding of appliedpiping and pipeline technology: design aspects of piping & pipeline system, selection of materials andtypes of pipes, flanges, valves and fittings, handling of those materials, welding & installation techniques andprocedures, and the operation, inspection and maintenance of oil & gas piping and pipeline systems.

TUJUAN TRAINING OPERATION OF PIPING AND PIPELINE

After completion of this special course participant will:

- Better understand the description, classification, requirement and specification of pipes, flanges, valvesand fittings used for oil and gas transportation operation

- Improve ability on design, installation and maintenance

- Interpret and evaluate pipeline operation performance data

- Identify and solve problems in oil and gas transportation pipeline

PESERTA PELATIHAN DESIGN OF PIPING AND PIPELINE

Technical and non-technical personnel of Oil and Gas Company who involves in or concern with design,selection, handling, installation, operation and maintenance of up-stream and down-stream oil and gaspipelines and/or industrial piping and those who responsible in stability of oil and gas or industrial fluidtransportation through pipeline system.

MATERI TRAINING INSTALLATION OF PIPING AND PIPELINE

In this specially designed practical course participants will learn from and discuss with professional instructor the following subjects:

- Oil & Gas Flow Stream Characteristics, Equipment and Facilities

- Hydrocarbon Properties and Oil & Gas Fluid Flow Characteristics

- Multi-phase Flow Gathering Lines, Manifolds and Accessory Equipment

- Oil & Gas Separation Stations and Facilities

- Water Treating and Disposal Equipment, Transportation Lines & Facilities

- Gas Treating and Processing Equipment, Transmission Lines & Facilities

- Piping & Pipeline Materials, Standards and Codes

- Steel Materials for Piping & Pipeline

- Metallic Materials for Valves, Flanges and Fittings

- Piping Manufacturing Methods and Variation ofProducts

- Oil & Gas Pipeline Related Standards and Codes

- API 5L Line Pipe Specifications

- Pipeline Operation Principles

- Piping & Pipeline Layout, Topography and Configuration

- Principles of Fluid Flow and Practical Flow Equation

- Multi-phase and Single-phase Oil & Gas Transportation/Transmission Practice

- Pump Operation in Oil and Water Pipeline system

- Compressor Operation in Gas Pipeline system

- ANSI B.31 Series Standards and Requirements

- Preliminary Selection of Economic Diameter for Minimum Investment

- Stress Formula for Wall Thickness and Design Pressure Computation

- Pipeline Economics Computation Methods

- Oil or Water Transportation Pipeline Design Concept

- Gas Transmission Pipeline Design Concept

- Pipeline Construction and Installation

- Choice of Design Procedure

- Stress Computation Methods in Design and Construction

- Pipeline Concrete Coating Parameters

- Hydrostatic Testing Requirements

- Construction/Installation Material Requirements

- Pipeline Maintenance and Pigging Operation

- Potential Operating Problems and Maintenance of Pipeline Systems

- Inspection Techniques for Potential Failures and Wall Thickness & MAWP Reduction

- Pipeline Cleaning and Pigging Operations

- Pipeline Internal Maintenance and Chemical Injection

- Pipeline External Maintenance and the Cathodic Protection

- Access Fittings for Maintenance, Chemical Injection and Monitoring

- Access Fitting Specifications, Configurations and Materials

- Chemical Injection, Fluid Sampling and Monitoring Equipment & Facilities

- Chemical Inhibitor, Scale Inhibitor and Biocide Materials

- On-line Corrosion and Scale Monitoring Techniques

- NACE Standards and Computation Methods for Pipeline Monitoring

INSTRUKTUR

Instruktur yang mengajar pelatihan Piping And Pipeline: Design, Installation, Operation ini adalah instruktur yang berkompeten di bidang Piping And Pipeline: Design, Installation, Operation baik dari kalangan akademisi maupun praktisi.

Jadwal Pelatihan Transform-mpi.com 2025 :

- Batch 1 : 30 – 31 Januari 2025

- Batch 2 : 13 – 14 Februari 2025

- Batch 3 : 11 – 12 Maret 2025

- Batch 4 : 16 – 17 April 2025

- Batch 5 : 15 – 16 Mei 2025

- Batch 6 : 25 – 26 Juni 2025

- Batch 7 : 16 – 17 Juli 2025

- Batch 8 : 6 – 7 Agustus 2025

- Batch 9 : 3 – 4 September 2025

- Batch 10 : 8 – 9 Oktober 2025 || 29 – 30 Oktober 2025

- Batch 11 : 13 – 14 November 2025 || 25 – 27 November 2025

- Batch 12 : 15 – 16 Desember 2025

Catatan : Jadwal dapat menyesuaikan dengan kebutuhan anda.

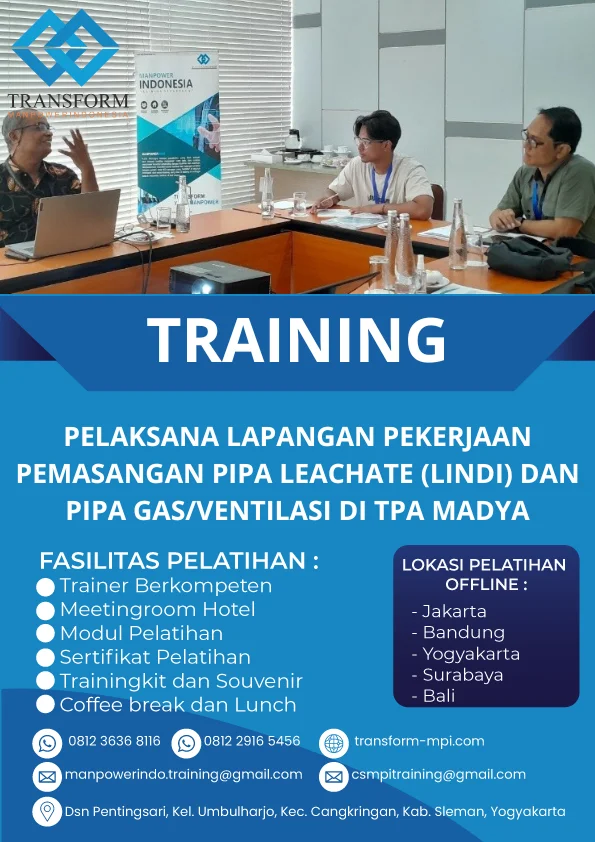

Biaya dan Lokasi Pelatihan :

- Jakarta :

- Bandung

- Yogyakarta

- Surabaya

- Malang

- Bali

- Lombok

Catatan : Biaya diatas belum termasuk akomodasi/penginapan. Apabila ada pertayaan mengenai materi, biaya, lokasi, jadwal dan penawaran lainnya, hubungi kami di nomor CS kami.

Fasilitas Pelatihan di transform-mpi.com:

- Penjemputan dari Hotel/Bandara/Stasiun/Terminal.

- Training Kit (Dokumentasi photo, Blocknote, ATK, Flashdisk, dll).

- Transportasi Peserta ke tempat pelatihan.

- 2x Coffe Break & 1 Lunch (Makan Siang).

- Training Room Full AC and Multimedia.

- Free Bag or Bagpackers (Tas Training).

- Softfile Foto Training

- Sertifikat Pelatihan.

- Souvenir Exclusive.